80kW Induction heating machine for heat treating of metals such as shafts, gears and hub wheel rings, steel bars hardening and tempering

High Frequency Induction Hardening Machine

What are the main characteristics of our induction hardening machine?

Parameters of DSP digital smart power supply

Type: XZZ-80

Input voltage: 380V/3phase/60Hz

Rated power (standard configuration): 80kW

Power regulation range: 5%-100% (digital regulation)

Power regulation accuracy: ±0 .5%

Oscillation frequency: 20-40KHz

Power factor: ≥97%

Operating mode Constant current: constant power random selection

Control core: High-performance DSP processor

Controls: Random switching of internal control and remote control

Control interface: Industrial touch screen + button

Communication interface: RS485

Cooling method: Forced water cooling combination

80kW Induction heating machine for heat treating of metals such as shafts, gears and hub wheel rings, steel bars hardening and tempering

What are the advantages of using an induction heating machine?

BEST TECHNOLOGY

• Speed. Heat generated by frequency

converter, arrives instantly.

• Accuracy. Just the right temperature, just

where it is needed and to the required depth.

• Controllability. Complete control over everything

heating process.

• Repeatability. Induction heating allows you

repeat the desired heating cycle exactly.

• Clean, safe, compact. No gas. No open

fire. No noticeable increase in ambient temperature

temperature. Ovens do not take up too much floor space.

Increased Durability: Metals such as shafts, gears and hub rings, and slewing bearings are subject to high wear and stress.

Hardening the surface and internal holes using a complete set of induction hardening machines improves their durability;

Making them more resistant to wear, deformation and damage.

PARTNER WORLDWIDE

• Knowledge of application areas. Almost 20 years old work experience has given us unsurpassed knowledge about various areas of application.

• Equipment technology. We design, manufacture, install and we service a full range of induction heating equipment.

• Possibility of using coils. Properly designed and manufactured and a maintained coil is critical for any induction operation.

• Know-how in the field of materials. Not only do we know more about induction heating than anyone else, we know more about how technology influences for your materials.

• Global coverage. Local presence. Worldwide network -work of representatives, production facilities and sales and service companies.

-

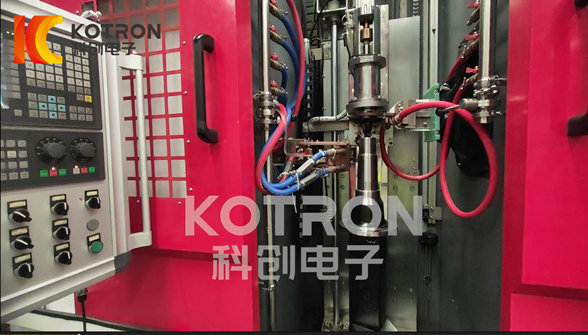

Horizontal hardening machines tools

This machine tool is composed of base, bed, water tank, workpiece rotation system, transformer-inductor feed moving system, load platform adjustment system, workpiece tightening device, hardening spray system, liquid return system, lubrication system, error prevention system, electrical control system, operating system and other parts.

-

Vertical type Hardening machine tool

General overview: This machine tool is a vertical CNC hardening machine tool. The Z-axis workpiece moves up and down, The A-axis rotates the workpiece table 360°. It can complete functions such as fixed-point timing overall hardening of shafts, continuous scanning hardening, segmented positioning

-

2022 New Technology--Synchronous Dual Frequency Induction Heating Machine

2022 New Technology--Frequency Mixing Induction Heating Machine Synchronous Dual Frequency

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.