-

Why should we choose induction heating equipment for metal heat treatment?

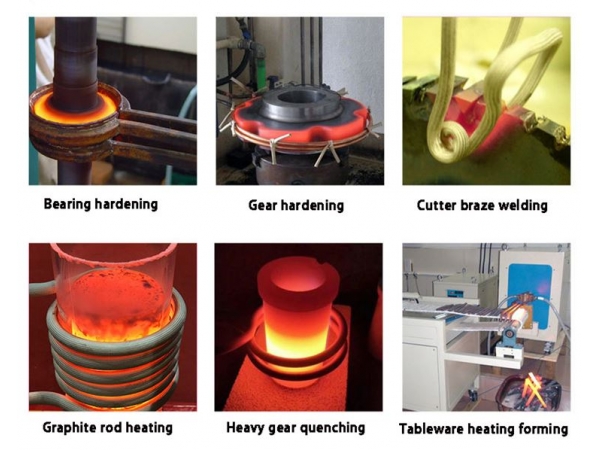

Why should we choose induction heating equipment for metal heat treatment? Induction heating equipment is an advanced device that uses the principle of electromagnetic induction to make the heated object generate heat itself. It mainly comprises a power supply, induction coil, capacitor, and other components. When alternating current passes through the induction coil, an alternating magnetic field will be generated around it, and an induced current (eddy current) will be generated inside the metal material in the magnetic field. Due to the resistance of the metal material itself, the eddy current will generate Joule heat during the flow process, so that the metal material will heat up rapidly. This heating method does not require direct contact with the heated object and has many advantages such as high efficiency, energy saving and environmental protection. First of all, induction heating is extremely efficient. Compared with traditional heating methods, energy is generated directly inside the workpiece, reducing the loss during heat transfer. It can heat the workpiece to the required temperature in a very short time, greatly improving production efficiency. For example, in metal forging, induction heating equipment can quickly heat the blank to the appropriate forging temperature, providing a guarantee for efficient...

-

How to solve the various defects that may occur during heat treatment?

How to solve the various defects that may occur during heat treatment? During industrial production, heat treatment is a key process, that can give specific properties and strength to workpieces. However, the heat treatment process is not always smooth sailing. Various defects often occur. These defects are like hidden “landmines”. If not taken seriously and solved, they will seriously affect the performance and service life of the workpiece. Today, let’s take a closer look at the various defects that may occur during heat treatment and how to control them. 1. Overheating and overburning Defect manifestation: Overheating: During the heating process of the workpiece, the austenite grains are significantly coarsened due to too high temperature or too long holding time. This will lead to a reduction in the strength and toughness of the workpiece, especially the impact of toughness. Over-burning: The heating temperature is too high, which not only makes the austenite grains coarse but also causes local oxidation or melting of the grain boundaries. The performance of the over-burned workpiece has seriously deteriorated and cannot be saved, so it can only be scrapped. Control method: Strictly control the heating temperature and holding time, and operate according to the process requirements....

-

What’s the advantages of Kechuang’s 40KW all-in-one Induction Heating equipment?

What's the advantages of Kechuang's 40KW all-in-one Induction Heating equipment? induction heat treatment solutions

-

Wire tempering production line and steel strip bluing

Wire tempering production line