- Induction Heating Machine

- 30KW all-in-one induction brazing machine

- Portable Induction Heating Machine

- 2022 New Technology–Synchronous Dual Frequency Induction Heating Machine

- Air Cooling Induction Heating Machine with Clamp magnet wires induction coils

- Analog Circuit Induction Heater

- 60kW All-in-one Induction Heating Machine – Crystal Growth

- 80KW Portable Air cooling Induction Heating Machine

- Tool Shrinking Machine

- DSP80KW Portable Induction Welding Machine with HHT

- High frequency Induction Heating Machine

- CNC Hardening Machine System

- Horizontal hardening machines tools

- Disc type Quenching machine tool

- Vertical type Hardening machine tool

- Multi-station indexing quenching machine tool

- Inclined vertical raceway CNC quenching machine tool

- cantilever type whole-tooth CNC quenching machine tool

- All-in-one CNC Induction Heating and Hardening Machine Tool

- Water Cooling System

- Transformer

- Induction Coils

- Auxiliary equipment

-

Mobile

(whatsapp/Wechat)+86-13937109134 -

E-mailinfo@zzkc.net

-

H-RB series laser fiber temperature sensor

H-RB series laser fiber temperature sensor

-

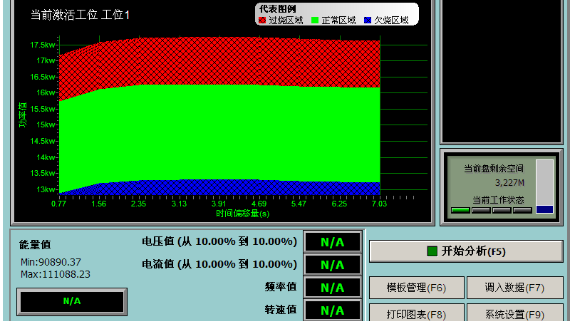

Energy Monitoring system

Energy Monitoring system Energy monitoring system for heating process of the quenching machine tool through the comparative analysis of various parameters, schedule data or curve of standard, set up the qualified lower limit on workpiece, can store a lot of process and history data of process, to facilitate later call and processing quality of the product traceability, might be used for remote monitoring parameters, can implement parameters to print. Basic function: it can compare the user’s stored curve with the actual curve for analysis, and display the instantaneous power, voltage, current value and heating time of the power supply through the curve and data; The upper and lower limits of power output can be set, with overlimit alarm function, such as “underburning” and “overburning”. Workpiece management function: The workpiece library can store tens of thousands of workpiece processing parameters, used to record and save the workpiece model, induction heating power output voltage, current, power, heating time, etc., and can set the upper limit and lower limit. Real-time display function of power output power: display the changing trend of voltage, current and power of induction heating power during heating process by curve. Curve and data storage function: the user in the process...