Induction Heating Experts

Induction Heating Equipment Manufacturer

Specializing in high and ultra-high frequency induction heating

Independent research and development.

10000+

Successfully Project Finished.

25+

Years Experience of RD & Manufacturing

80000+ sqft

Manufacturing plant area

300+

Colleagues & counting more daily

Our Products

Induction Heating Machine

MF Induction heating machine

Medium Frequency Induction Heating Machine 0.5kHz-10kHz

UF Induction Heating Machine

Ultrasonic Frequency Induction Heating Machine 10Hz-50kHz

HF Induction Heating Machine

High Frequency Induction Heating Machine 50kHz-200kHZ

UHF Induction Heating Machine

Ultra-high Frequency Induction Heating Machine 200kHz-1000kHz

MF Induction heating machine

Medium Frequency Induction Heating Machine 0.5kHz-10kHz

UF Induction Heating Machine

Ultrasonic Frequency Induction Heating Machine 10Hz-50kHz

HF Induction Heating Machine

High Frequency Induction Heating Machine 50kHz-200kHZ

UHF Induction Heating Machine

Ultra-high Frequency Induction Heating Machine 200kHz-1000kHz

Our System

Induction Heating System

Quenching and Tempering Machine

A quenching and tempering machine is a piece of equipment that performs a heat treatment process, first rapidly cooling (quenching) metal components to increase hardness and then reheating (tempering) them to reduce brittleness and improve ductility and toughness.

Induction Heating Machine

Induction heating is a process that uses electromagnetic induction to generate heat in conductive materials, such as metals, by exposing them to an alternating magnetic field.

Induction Forge Machine

Induction forging is a metal forming process that uses an induction heater to preheat metals to a malleable state before deforming them with a press or hammer.

Induction Brazing Machine

An induction brazing machine is a device that uses electromagnetic induction to heat and join metal components by melting a filler metal (brazing alloy) with a lower melting point than the base metals, which flows into the joint to form a bond.

Our Feature

Efficient Self-protection

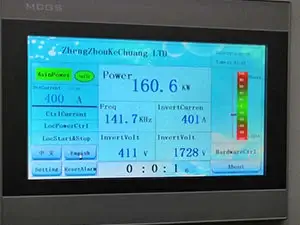

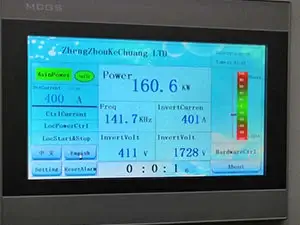

Digital Control System

Ultra-high Precise temperature control, efficient energy matching, and intelligent operation monitoring, significantly improving heating accuracy, energy efficiency, and production safety.

Dual‐frequency

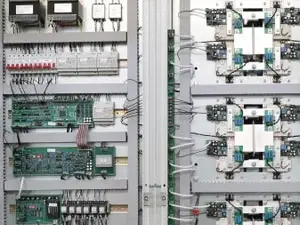

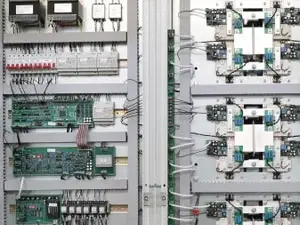

DSP+IGBT

The low-loss switching performance of IGBTs and the high-precision digital control of DSP enable energy conversion efficiency of up to 98%, nanosecond-scale dynamic response, and intelligent protection functions.

Efficient Self-protection

Digital Control System

Ultra-high Precise temperature control, efficient energy matching, and intelligent operation monitoring, significantly improving heating accuracy, energy efficiency, and production safety.

Dual‐frequency

DSP+IGBT

The low-loss switching performance of IGBTs and the high-precision digital control of DSP enable energy conversion efficiency of up to 98%, nanosecond-scale dynamic response, and intelligent protection functions.

KC Induction

About US

Professional Induction Heating Solution

ONE STOP SERVICE INDUCTION HEATING EQUIPMENT

Full set of induction heating equipment, including heat treatment power supply, transformer, inductor, water cooling system, robotic arm, and conveyor belt. Manufacturers and suppliers.

Real factory, Best price & high quality.

Induction heating technology leads independent research and development, independent supply chain

- Original factory

- 7*24 hour Services

- Leading technology

- Free OEM/ODM

Real manufacturer

Own factory building

Own production line

Independent R&D team

Multiple patented technologies

Frequently Asked Questions

Learn More From

A: We produce and export all kinds of induction heating machine. We also can design and develop the induction heating machine according to your requirements.

We are a factory with direct sales. You are welcome to conduct video factory inspections or visit us at any time.

We can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance.

For most of our standard machines, we maintain regular inventory. We can initiate the shipping process within seven days after receiving your payment. For customized machine orders, the production timeline typically ranges from 30 to 90 days.

Our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

In the guarantee time (1 year) , we will send the spare parts to you for free. And provide the technical consultant for anytime.if more terrible,we can send our engineers to your factory.We will provide same good after-sale service as the pre-sale service, any of your questions,we will be replied within 12 hours.

Cooperative Partner